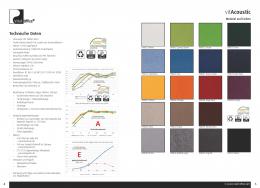

vitAcoustic PET Acoustic Material Data Sheet / Technical Data:

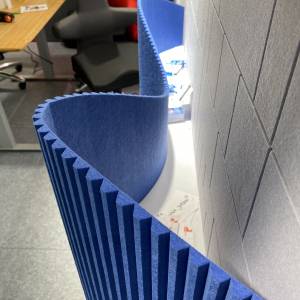

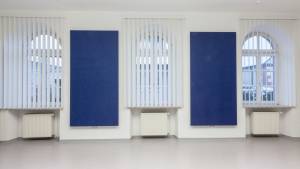

- vitAcoustic PET sheets

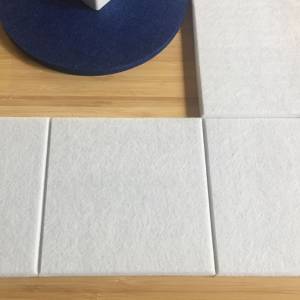

- Textile panels similar to felt, but made of synthetic fibers

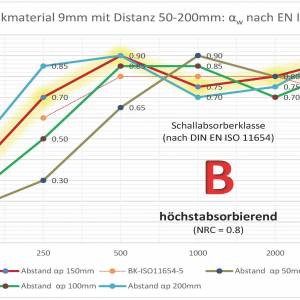

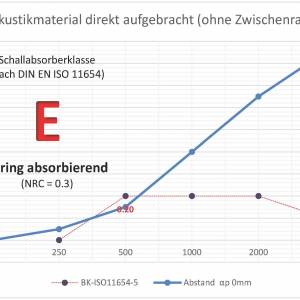

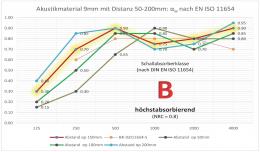

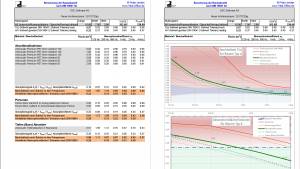

- Highly absorbent (details in the application are to be considered! See test curves)

- B1 fire class

- Without ingredients, without glues, without dyes .. Zero VOC .. good for allergy sufferers

- Colors: 19-50 bearing colors

- Composition: 100% PET (Polyethylenterephthalat / Polyester)

- Dimensionally stable plate

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>

/a>